Welcome to RICHI Machinery co., ltd

Biomass Pellet Plant For Sale

Biomass Pellet Plant

What is a biomass pellet plant? Simply put, the main task of the biomass pellet plant is all the biomass raw materials pellet manufacturing.

Now the new biomass pellet plant design can meet the multi-function and wider application range. In addition to raw materials with special properties, for general raw materials, such as forest waste (logs, branches, planks), agricultural waste (straw, rice husk, grass), urban waste (waste paper, meal leftovers), other wastes (husks, fibers, animal manure), etc., the pelletizing process of these raw materials basically includes crushing, drying, pelletizing, cooling and packaging.

Therefore, the following list is the main production equipment of the biomass pellet plant. Of course, the whole biomass pellet production line has many other auxiliary equipment besides these main production equipment. If you are interested in this biomass pellets industry and want to establish a biomass pellet factory, contact us to get a complete biomass pellet plant equipment list and quotation.

APPLICATIONS

Biomass pellet manufacturing

FINAL PELLETS

6mm-12mm biomass pellets

CAPACITY

1-40TPH<Can be customized>

TOTAL POWER

According to biomass pellet equipment

Main Equipment of Biomass Pellet Plant

- Model: SFSP56*40/SFSP66*60/SFSP66*80/SFSP66*100

- Capacity: 3-5T/H, 6-9T/H, 10-13T/H, 12-16T/H

- Raw Materials: all the biomass raw materials

- Main Application Scenario: raw material crushing section of biomass pellet plant

- Brand Name: RICHI Dryer Machine

- Model: ф1200*120000, ф1500*150000, ф1800*180000, ф2400*100000, ф2400*100000*3

- Application: Applicable to low-temperature continuous drying material in large quantity, such as sawdust, wood chips, grass, straw, hemp, hops, dregs and etc.

- Main Application Scenario: raw material drying section of biomass pellet plant

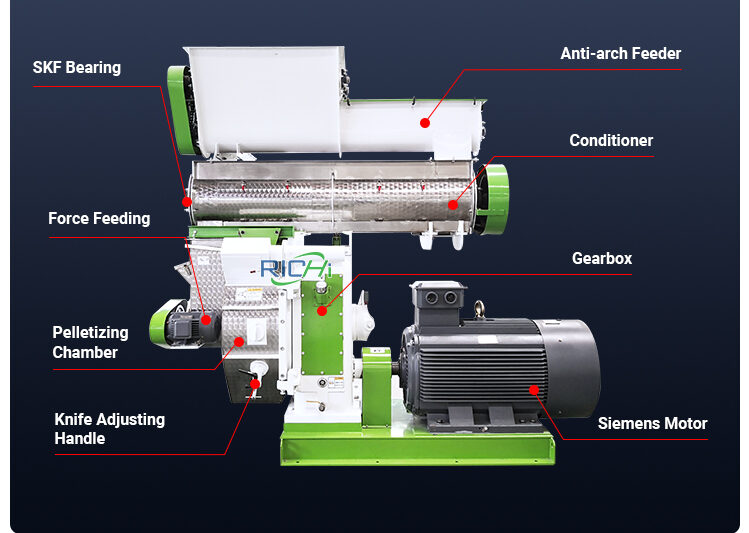

The biomass pellet making machine is the core production equipment of the biomass pellet plant. It consists of feeder, conditioner, pelletizing chamber, ring die and pressure roller, core shaft, motor and other components, which play a decisive role in pellet quality and output.

- Power: 30-300KW

- Capacity: 0.5-10T/H

- Pellet Size: 6-12mm

- Model: SKLN11*11, SKLN14*14, SKLN17*17, SKLN20*20, SKLN24*24

- Capacity: 1.5-2T/H, 3-5T/H, 5-8T/H, 9-12T/H, 13-18T/H

- Application: Cooling of high temperature pellet after pelleting

- Main Application Scenario: biomass pellet plant post-processing section

- Brand Name: RICHI Wood Pellet Packing Machine

- Model: DCS-C50/D, DCS-A50/D, DCS-B50/D, DCS-B50/S, DCS-A50/Y

- Application: Mainly used in biomass pellet plant. As the last step of the equipment, the finished product is packaged for storage and transportation.

- Main Application Scenario: finished product packaging section of biomass pellet production line

How Does A Biomass Pellet Plant Work?

The complete biomass pellet factory production process includes the following steps, which are for reference only.

- Preparation of raw materials. At least there must be a warehouse or vacant space for the storage of raw materials.

- Processing of raw materials. There will be slicing equipment, crushing equipment, and drying equipment in this section, and the specific equipment configuration is determined according to the properties of the raw materials.

- Pelleting section. The biomass pellet making machine is the core equipment of the entire biomass pellet plant, which determines the quality and output of biomass pellet manufacturing.

- Cooling of biomass pellets. The temperature of the biomass pellets coming out of the biomass pelletizer is very high, and cooling equipment is needed to reduce the biomass pellets to below room temperature.

- Packaging of finished products. According to the output, we can provide customers with ordinary automatic packing system (about 50kg per bag), or large pellets packing system with one ton per bag.

How Do I Start A Biomass Pellet Manufacturing Business?

If you want to start a biomass pellet plant business, please make sure that you have sufficient biomass materials. The biomass pellet production business usually has a large amount of biomass waste materials. The sources of raw materials are usually: forest waste(branches, leaves, planks, wood blocks), agricultural waste(crop straws, nut shells), urban waste(waste paper, meal leftovers, household garbage) , and all other organic waste.

Biomass pellets are produced in a biomass pellet factory, and all biomass pellet production equipment is carefully arranged. Therefore, it is necessary to understand the steps involved in the production of biomass pellets so that you can hire labor accordingly. The following is the general biomass pellets manufacturing process. (Read more: complete biomass pellet production line >>)

- The biomass raw materials are chiped and crushed by chipper and crusher into small sizes sawdust.

- Then the sawdust are passed by a large dryer.

Then they are grounded in the biomass pellet plant.

- Lastly, they are cooled down and packed to be sold.

To select an open space. If your space is small, it is recommended to start with a small-output biomass pellet factory business. Make sure your location is close to the raw materials so you can save on transportation costs. It is better to have space to store the finished biomass pellets.

It is very important to choose the correct biomass pellet production equipment manufacturer. Only by purchasing high-quality biomass production equipment and establishing a biomass pellet plant can the quality and output of biomass pellets be guaranteed.

Biomass Pellet Plant Investment Cost

Want to startup biomass pellet factory business? Contact us for biomass pellet plant investment cost and biomass pellet plant production cost.

What We Do

Biomass Pellet Plant Design & Manufacturer - RICHI

We are a professional manufacturer and supplier of biomass pellet manufacturing plant for sale. So far, we have designed and installed more than hundreds of biomass pellet plant solutions for customers all over the world.

Consulting

Contact us, first you need to determine the biomass pellet production plan and biomass pellet plant design layout.

Delivery

For large engineering equipment, we usually ship to the customer’s country or nearby ports.

Installation

We have a overseas installation team with rich experience in equipment installation. Also teach customers how to make pellets with biomass pellet plant, and routine maintenance.

Our Services

What Can We Do For Customers About Biomass Pellet Plant?

Looking for biomass pellet production equipment manufacturers? Want to start your own biomass pellet manufacturing plant business? RICHI will help you to startup biomass pellet factory business.

Biomass Pellet Plant Design

We have a wealth of experience and can design a complete production plan design for a biomass pellet factory for customers.

Biomass Pellet Machine Manufacturing

RICHI produces and supplies all the pellet production related equipment and accessories for customers about biomass pellet plant.

Fast Delivery

For all the equipment of the complete biomass pellet production plant, we can ship it to the local or nearby port within two months after the customer pays.

Global Installation

Our overseas installation team not only helps customers solve biomass pellet plant installation problems, but also trains customers on how to operate and maintain.

Our Achievements

Biomass Pellet Plant Solutions From RICHI Machinery

Development experience

Product category

Export country

Pellet Solutions