RICHI MACHINERY

blog center

I hope that with the help of RICHI, you can have smooth sailing in the pellet production industry.

As a professional manufacturer and supplier of pellet production equipment, RICHI has received more and more attention from customers during the 26 years of development, not only because of our excellent technology and high-quality products, but also because of our service, for RICHI, customers are always the first.

What Kind of Machine Turns Wood Chips into Pellets?

In today’s era of pursuing sustainable energy、low carbon and environmentally friendly production, converting wood chips and other biomass waste into pellets is not only an effective way to achieve resource reuse, but also brings innovative solutions to the energy industry. Pellets, as a clean and renewable energy source, are not only used for commercial and domestic heating, but also for industrial power generation, animal beds, etc., and its production process deserves to be explored in depth. In this article, we’ll look at the machinery that transforms wood chips into pellets – the wood pellet mill – how it works, and why specialized equipment is essential to the process. Wood pellet mill Wood chip pellet mill, also known as biomass pellet mill, is the core equipment for biomass pellet production. It compresses wood chips into solid particles through high pressure, a process that not only improves the burning efficiency of wood

The Progressive Influence and Role of Advanced Wood Pellet Machine in Contemporary Energy Systems

In an era marked by growing concerns about climate change and environmental sustainability, the significance of biomass pellet production cannot be overstated. Biomass pellets are a renewable energy source that has gained traction as an environmentally friendly alternative to fossil fuels. This article explores the critical role biomass pellet production plays in reducing carbon emissions and its broader impact on mitigating climate change. Introduction The Carbon Emission Challenge The world is grappling with the adverse effects of carbon emissions, primarily driven by the burning of fossil fuels such as coal, oil, and natural gas. These emissions contribute significantly to the greenhouse effect, leading to global warming and climate-related disasters. Biomass Pellets as a Solution Biomass pellets are derived from organic materials like wood, agricultural residues, and even dedicated energy crops. Unlike fossil fuels, biomass is considered carbon-neutral because the carbon dioxide (CO2) released during combustion is offset by the CO2

The Significance of Biomass Pellet Production in Reducing Carbon Emissions

In an era marked by growing concerns about climate change and environmental sustainability, the significance of biomass pellet production cannot be overstated. Biomass pellets are a renewable energy source that has gained traction as an environmentally friendly alternative to fossil fuels. This article explores the critical role biomass pellet production plays in reducing carbon emissions and its broader impact on mitigating climate change. Introduction The Carbon Emission Challenge The world is grappling with the adverse effects of carbon emissions, primarily driven by the burning of fossil fuels such as coal, oil, and natural gas. These emissions contribute significantly to the greenhouse effect, leading to global warming and climate-related disasters. Biomass Pellets as a Solution Biomass pellets are derived from organic materials like wood, agricultural residues, and even dedicated energy crops. Unlike fossil fuels, biomass is considered carbon-neutral because the carbon dioxide (CO2) released during combustion is offset by the CO2

Future Trends in Pelletization Equipment

In the ever-evolving landscape of industrial processes, pellet mill machine plays a crucial role in transforming raw materials into valuable products. Whether in the pharmaceutical, food, or agriculture industries, pelletization is an essential step in creating uniform, easily transportable, and efficiently processed materials. Today, we will delve into the future trends of pelletization equipment, exploring how advancements in technology, sustainability, and automation are shaping this critical facet of manufacturing. Increased automation of the pelletizing process One of the primary reasons for the escalating automation of pelletizing is the quest for precision and consistency. Automation eliminates the variability introduced by human operators. Modern automated systems can meticulously control factors like pellet size, shape, and quality, resulting in products of superior uniformity. Industries today face ever-growing demands for their products. The manual or semi-automated processes of the past simply cannot keep up. Increasing automation in pelletizing allows manufacturers to scale up their

Why do we recommend choosing a ring die pellet machine?

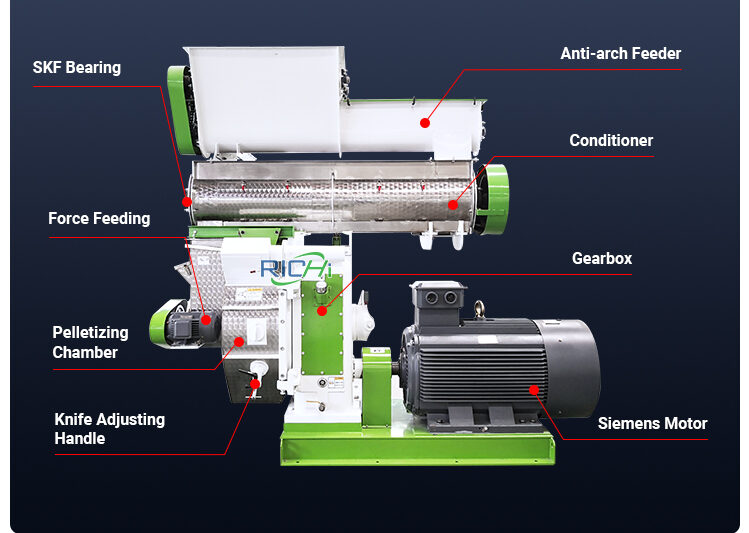

Ring die pellet machine is one type of pelletizing equipment. It is commonly used in the production of animal feed, wood pellets, and biofuels. This kind of pellet machine is known for its efficiency, durability, and ability to produce high-quality pellets on a large scale. The feeder feeds raw materials such as sawdust, shavings, and other biomass into the pelletizer chamber, forming pellets through high temperature and pressure. The ring die has small holes, called die holes, that are spaced evenly around its circumference. As the raw materials are forced through the die-holes, they are compressed and shaped into small, uniformly-sized pellets. One of the key advantages of the ring die pellet machine is its ability to produce high-quality pellets. Because the raw materials are forced through the die holes under high pressure, the resulting pellets are dense and have a smooth, uniform surface. This makes them less susceptible to