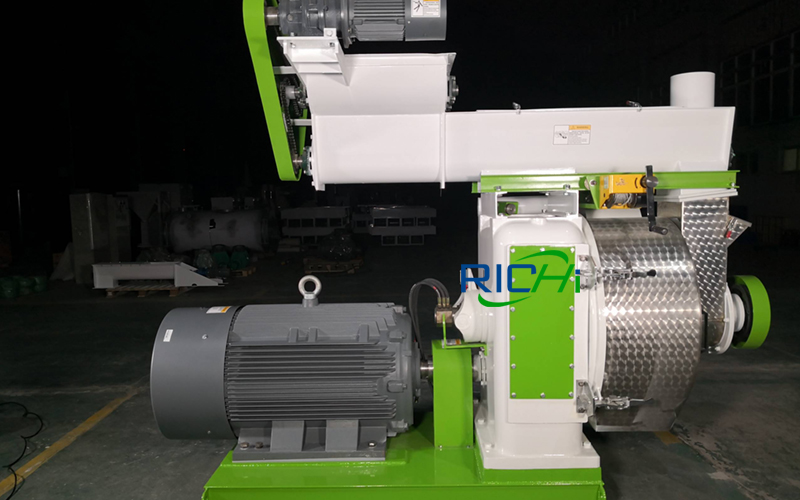

MZLH320 Wood Pellet Machine

MZLH320 series wood pellet machine ensures high capacity and efficient control of the wood pelleting process. The mzlh series ring die wood pellet mill machine is dimensioned for large and designed with exchangeable wear parts.

Find More Wood Pellet Machines For Sale

- Power: 380volt, 37kw, 50hz

- Application: Used for the production of biomass pellets, wood pellets, agricultural and forestry waste pellets

- Pellet size: 6-12mm

- Power: 380volt, 55kw, 50hz

- Application:Used for the production of biomass pellets, wood pellets, agricultural and forestry waste pellets

- Pellet size: 6-12mm

- Power: 380volt, 110kw, 50hz

- Application:Used for the production of biomass pellets, wood pellets, agricultural and forestry waste pellets

- Pellet size: 6-12mm

- Power: 380volt, 160kw, 50hz

- Application:Used for the production of biomass pellets, wood pellets, agricultural and forestry waste pellets

- Pellet size: 6-12mm

- Power: 380volt, 250kw, 50hz

- Application:Used for the production of biomass pellets, wood pellets, agricultural and forestry waste pellets

- Pellet size: 6-12mm

- Power: 380volt, 280kw, 50hz

- Application:Used for the production of biomass pellets, wood pellets, agricultural and forestry waste pellets

- Pellet size: 6-12mm

Wood Pellet Machine Video

MZLH320 wood pellet machine is new energy equipment for biomass. It is a pelletizing equipment for the production of wood pellets; it uses eucalyptus, birch, poplar, fruitwood, bamboo chips, and crop straws as raw materials, through crushing, drying, pelletizing, cooling, packaging, and other processes to produce finished wood pellets.

The finished wood pellets are mainly used in biomass power generation, industrial boilers, fireplaces, household barbecues, and other equipment.

Also, welcome everyone to follow our wood pellet machine youtube channel for more video content.

Wood Pellet Machine Technical Parameter

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

|---|---|---|---|---|---|---|

| Anti-caking Feeder Power | 1.5KW | 1.5KW | 1.5KW | 2.2KW | 3KW | 3KW |

| Forced Feeder Power | 0.55KW | 0.55KW | 0.55KW | 0.75KW | 1KW | 1KW |

| Pellet Machine Power | 37KW | 55KW | 110KW | 160KW | 250KW | 280KW |

| Capacity(wood sawdust,biomass) | 300-400KG/H | 500-700KG/H | 1.0-1.2 T/H | 2.0-2.5 T/H | 2.5-4 T/H | 3-4.5 T/H |

| Capacity(grass,straw) | 600-800KG/H | 800-1000KG/H | 1.5-2 T/H | 3-4 T/H | 5-7 T/H | 8-10 T/H |

| Capacity(organic fertilizer) | 1-2 T/H | 3-4 T/H | 5-6 T/H | 7-8 T/H | 9-10 T/H | 10-12 T/H |

| Final Pellet | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm |

| Weight(KG) | 2500 | 3500 | 4000 | 4500 | 5000 | 5500 |

| Dimension(mm) | 2200*900*1300 | 2500*1100*1600 | 2800*1150*1730 | 3000*1260*1860 | 3300*1500*2000 | 3500*1600*2180 |

Why choose wood pellet machine from RICHI Machinery

Prevent

Connected to the air duct, there is a mesh in the box to prevent the finished pellets from overflowing

Frequency

Due to the characteristics of biomass raw materials, we have added a variable frequency feeder with anti-caking device

Motor

We promise that all motors use Siemens motors

Protect

Protect machine(Producting main shaft, rotor and ring die)

Lifting Device

This small lifting device can help user to replace the very heavy ring die and roller assembly

Ring Die

304 stainless steel ring die, corrosion resistance, Full automatic CNC ring die drilling machine and vacuum heat treatment technology

What is wood pellet machine?

MZLH320 series wood pellet machine is new energy equipment for wood and biomass. It is pelletizing equipment for the production of wood pellets.

It uses eucalyptus, birch, poplar, fruit, bamboo, crop straw, and other biomass materials as raw materials, through crushing, drying, pelleting, cooling, packaging, and other processes to produce finished wood pellets. Its finished pellets are used in biomass power generation, industrial boilers, fireplaces, household barbeque, etc.

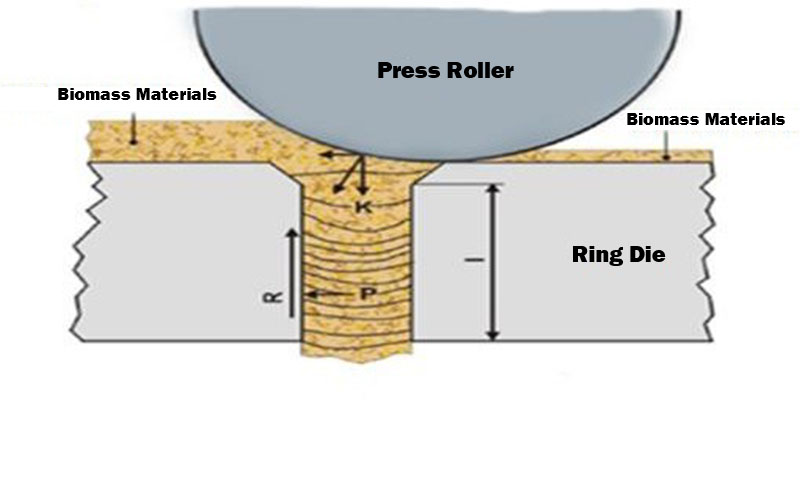

How does a wood pellet machine work?

The powdered raw materials enter the pelleting chamber of the mzlh320 wood pellet machine through the conditioner. They are mechanically compressed under high temperatures and pressure.

Then, these raw materials are polymerized and shaped through the holes of ring die. Finally, it is cut to the required length by a cutter. This process is called pelletizing.

How much does a wood pellet machine cost?

As a professional pellet machine manufacturer, RICHI needs to talk to some customers who want to buy wood pellet machines or enter the pelletizing industry for the first time.

Generally, the deciding factor of the wood pellet machine price is the output, but different raw materials also restrict the output. For example, for the same wood pelletizer, the production of grass-based raw materials is higher than that of sawdust-based raw materials.

Different raw materials require pre-treatment processes, such as wood chipping and crushing. With different displays and different natural material processing, we can design various schemes and configurations to ensure that it is the most suitable for customers.

Understand? So the important for us is, what are your raw materials and the expected pellet output? Contact us for wood pellet machine prices and customized wood pellet production lines.

Where to buy wood pellet machine from China?

We recommend that customers need to determine the following points before buying a wood pellet machine from a specific factory:

- Is it an actual pellet machine manufacturer? Where is the address? Can I visit it?

- Is the whole pellet production line designed according to different raw materials?

- How about the production delivery capacity and delivery time? (Single machine within half a month, production line within one month to two months)

- For industrial and commercial activities, we recommend using ring die pellet machines.

RICHI is a professional pellet machine manufacturer in China and has a variety of pellet machines for sale. In 26 years of development, we have exported to the United States, Australia, Canada, New Zealand, Ireland, Italy, Germany, Britain, Malaysia, Indonesia, Thailand, and other countries.

Buy Wood Pellet Machine Today

Application of Wood Pellet Machine in Production Line

Wood pellet machine is the core equipment of the whole pellet production line. If your raw material is already wood sawdust, a single pellet mill can produce wood pellets as long as the moisture is kept under certain conditions; but if your raw material is logs, branches, shavings, or other wood waste, then A complete wood pellet production line is needed.

RICHI Machinery already has complete application cases of wood pellet machine in many countries. The two pellet plants here are for reference only. If you want to invest in a wood pellet production plant, please contact us today for a quote for a complete pellet production solution and all equipment.

Wood Pellet Production Line in Poland

- Project name: wood pellet plant

- Project Country: Poland

- Project Date: January 23, 2019

- Project capacity: 2-3T/H

- Particle size: 4mm

- Installation period: 15 days

- Factory size (L*W*H): 26m*4m*8m

- Main raw material: wood logs

Wood Pellet Plant in Indonesia

- Project name: wood pellet plant

- Project Country: Indonesia

- Project Date: June 15, 2018

- Project capacity: 1-1.5T/H

- Particle size: 6-8mm

- Installation period: 20 days

- Workshop size (L*W*H): 20m*10m*15m

- Main raw materials: logs, sawdust, wood chips

RICHI Service

Comprehensive services for the entire life cycle of a wood pellet plant. Space-saving structure. Standardization.

Wood Pellet Machine For Sale – The Related Guide

How To Make A Pellet Machine

- Main structure of ring die wood pellet making machine

The ring die wood pellet machine is mainly composed of a feeder, a conditioner, a pellet maker, an adjustment mechanism and a lubrication system.

- The feeder is composed of an electromagnetic speed regulating motor, a reducer, a coupling, auger shaft and auger shell.

- The speed-regulating motor is composed of a variable-frequency motor and a reducer. It is used in conjunction with a frequency converter. The speed-regulating motor can be controlled by the frequency converter to change its output speed.

- The feeding auger is composed of the auger shell, the auger shaft and the bearing with a seat, etc., and the auger shaft is driven by an adjustable speed motor through a coupling.

- The conditioner is composed of a motor, a transmission mechanism, a quenched and tempered rotor, a shell, and a steam inlet. Its function is to inject steam, temper the powdered materials to a certain temperature and humidity, and then send them into the granulating chamber for granulation.

- The conditioner shell is made of stainless steel.

- Technology Center

RICHI has advanced processing and testing equipment, such as large CNC plasma cutting machine, CNC large drilling machine, CNC shearing machine, CNC bending machine, CNC gantry milling machine, CNC sawing machine, CNC dynamic balancing machine, CNC universal milling machine, three CNC lathes. , large-scale professional paint room and other advanced production equipment. Henan Richi Machinery Co., Ltd. has developed more than 50 series of products such as wood pellet making machine with excellent performance.

- Engineers And Technicians

RICHI Technology Research and development center has more than 300 professional R & D team, 80 senior engineers with many years of R & D and design experience, a group of innovative talents who are capable and vigorous in process equipment and control engineering.

- Manufacturing Strength

- 10,0000 square meters

- 30 sets of advanced manufacturing and testing equipment

- 3 heavy-duty modernized manufacturing and assembly workshops.

- Reliable Pellet Machine Expert

After years of development, we have experienced expert engineers. Not only are we constantly innovating the production and manufacturing of pellet mill, but we can also give customers professional guidance and suggestions on making wood pellets from sawdust.

How Does A Wood Pellet Machine Work

The wood pellet mill is mainly composed of main motor, transmission mechanism, rotor, ring die, pressure roller, scraper, cutter assembly, body and door, etc.

The powdery material tempered by the conditioner is uniformly sent to the pressing zone composed of two pressure rollers and ring die by the rotating feed cone and two deflection scrapers on the front plate, and passes through the ring die and the pressure roller.

The relative rotating part gradually squeezes the powdery material into the ring die hole to form, and continuously extrudes to the outer end, and the formed particles are cut into the required length by the cutter, and finally the formed particles are discharged from the discharge port.

How To Build A Wood Pellet Mill

Due to the vigorous development of the pellet market, whether it is hardwood sawdust pellets, bbq pellet, wood pellets for smoking grill, or biomass pellets, many investors want to enter the pellet industry, so how to establish a complete wood pellet production line?

- It must have land first, and land can be built to build a pellet mill, collect raw materials, and collect products. But you have to choose a good place, usually a place close to the raw materials or convenient transportation. It is best to have both of them.

- Budget. Plant construction funds, equipment purchase funds, preliminary operating funds, etc.

- Plant construction

When designing the plant, plan every inch of land as much as possible and reasonably.(But don’t worry, because RICHI will help you design and plan the most reasonable plant) - Buy equipment. Before buying a pellet machine, you must first understand the product quality of the equipment company and compare it with similar companies. For example: RICHI Machinery is a leading professional manufacturer and exporter of wood pellet machines in China. CPM is the largest granulator company in the Americas. The position of ANDRITZ and Buhler in Europe. and many more.

- Equipment installation, usually the wood pellet equipment company sends personnel to guide the installation on site.

How To Make Wood Pellets From Sawdust

With the development of pelletizing technology, making your own wood pellets has become more and more simple, you only need to pay attention to the following points:

- Raw materials. If your raw materials are relatively large wood logs, then in the first step you need equipment that can peel and slice the trees; then use a shredder to crush the relatively large pieces of wood to sawdust below 5mm; if your raw materials are some forest waste, small branches, wood chips, etc., you can crush them directly without chipping.

- At this time, attention should be paid to the moisture content of the raw materials, and then if the wood sawdust are too wet, it needs to be dried to a moisture content of about 8-12% (note: the moisture content can be tested with a moisture meter). If you only make small-volume pellets, you can spread the sawdust on the ground and let it air dry.

- Pelletizing process. Start the pellet production equipment, and evenly send the wood sawdust into the hopper of the pellet mill machine through the conveying equipment. The rotating ring die and press roller squeeze the sawdust and force it through the die hole. The high pressure will compact the pellets, and the high temperature will melt the lignin in the wood sawdust and become sticky. Therefore, the wood sawdust produced has high pellet density and smooth and even bright surfaces.

- After the pelleting is completed. The wood pellets just coming out of the sawdust pellet mill are very hot, so they must be cooled to room temperature before use or storage.

You can find that making pellets with sawdust is just an easy task! But sawdust pellets can save you a lot of costs, and even make you profit. Therefore, it is a wise choice to invest in pellet production.