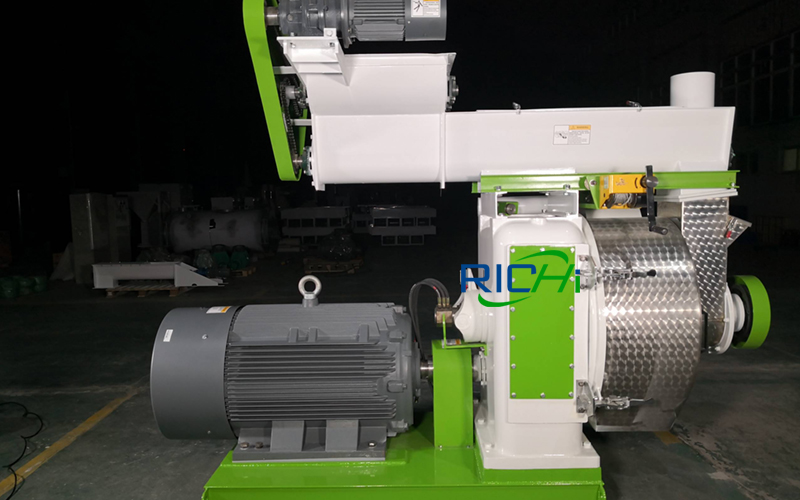

RICHI MACHINERY MZLH420 SERIES

Wood Pellet Mill

This ring die electric mzlh420 wood pellet mill is recommended for the pellet mill plant. Due to the power and voltage, it is not recommended for household pelletizing. It is very suitable for making alfalfa pellets, forage pellets, wood sawdust pellets, and other biomass pellets. RICHI Machinery, made in China, ships worldwide.

Our mzlh420 wood pellet mills are suitable for pelletizing many kinds of raw materials, such as forest waste, furniture factory waste, waste wood, pallets, etc.

RICHI Wood Pellet Mills Series

- Power: 380volt, 37kw, 50hz

- Application: Used for the production of biomass pellets, wood pellets, agricultural and forestry waste pellets

- Pellet size: 6-12mm

- Output: 300-400kg/h for wood and biomass; 600-800kg/h for grass and straw; 1-2t/h for organic fertilizer

- Power: 380volt, 55kw, 50hz

- Application:Used for the production of biomass pellets, wood pellets, agricultural and forestry waste pellets

- Pellet size: 6-12mm

- Output: 500-700kg/h for wood and biomass; 800-1000kg/h for grass and straw; 3-4t/h for organic fertilizer

- Power: 380volt, 110kw, 50hz

- Application: Used for the production of biomass pellets, wood pellets, agricultural and forestry waste pellets

- Pellet size: 6-12mm

- Output: 1-1.2t/h for wood and biomass; 1.5-2t/h for grass and straw; 5-7t/h for organic fertilizer

- Power: 380volt, 160kw, 50hz

- Application: Used for the production of biomass pellets, wood pellets, agricultural and forestry waste pellets

- Pellet size: 6-12mm

- Output: 2-2.5t/h for wood and biomass; 3-4t/h for grass and straw; 7-8t/h for organic fertilizer

- Power: 380volt, 250kw, 50hz

- Application: Used for the production of biomass pellets, wood pellets, agricultural and forestry waste pellets

- Pellet size: 6-12mm

- Output: 2.5-4t/h for wood and biomass; 5-7t/h for grass and straw; 9-10t/h for organic fertilizer

- Power: 380volt, 280kw, 50hz

- Application: Used for the production of biomass pellets, wood pellets, agricultural and forestry waste pellets

- Pellet size: 6-12mm

- Output: 3-4.5t/h for wood and biomass; 8-10t/h for grass and straw; 10-12t/h for organic fertilizer

Wood Pellet Mill Technical Parameter

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

|---|---|---|---|---|---|---|

| Anti-caking Feeder Power | 1.5KW | 1.5KW | 1.5KW | 2.2KW | 3KW | 3KW |

| Forced Feeder Power | 0.55KW | 0.55KW | 0.55KW | 0.75KW | 1KW | 1KW |

| Pellet Machine Power | 37KW | 55KW | 110KW | 160KW | 250KW | 280KW |

| Capacity(wood sawdust,biomass) | 300-400KG/H | 500-700KG/H | 1.0-1.2 T/H | 2.0-2.5 T/H | 2.5-4 T/H | 3-4.5 T/H |

| Capacity(grass,straw) | 600-800KG/H | 800-1000KG/H | 1.5-2 T/H | 3-4 T/H | 5-7 T/H | 8-10 T/H |

| Capacity(organic fertilizer) | 1-2 T/H | 3-4 T/H | 5-6 T/H | 7-8 T/H | 9-10 T/H | 10-12 T/H |

| Final Pellet | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm |

| Weight(KG) | 2500 | 3500 | 4000 | 4500 | 5000 | 5500 |

| Dimension(mm) | 2200*900*1300 | 2500*1100*1600 | 2800*1150*1730 | 3000*1260*1860 | 3300*1500*2000 | 3500*1600*2180 |

Features of RICHI Wood Pellet Mill

Prevent

Connected to the air duct, there is a mesh in the box to prevent the finished pellets from overflowing

Frequency

Due to the characteristics of biomass raw materials, we have added a variable frequency feeder with anti-caking device

Motor

We promise that all motors use Siemens motors

Protect

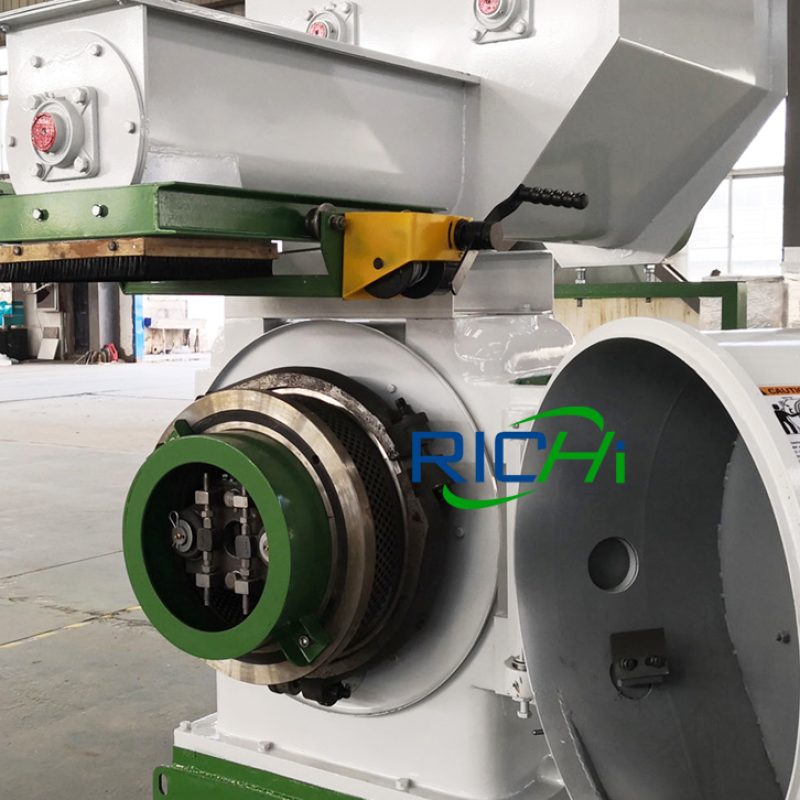

Protect machine(Producting main shaft, rotor and ring die)

Lifting Device

This small lifting device can help user to replace the very heavy ring die and roller assembly

Ring Die

304 stainless steel ring die, corrosion resistance, Full automatic CNC ring die drilling machine and vacuum heat treatment technology

Startup Pelletizing Business With RICHI

RICHI Machinery is one of the professional wood pellet mill manufacturers in China. We have exported to more than 110 countries and regions. Contact us immediately to start the wood pellet production business.

How To Make Pellets By Wood Pellet Mills

Wood pellet mill is a new energy pelleting equipment for biomass materials. It is a pelletizing equipment for the production of wood pellets; it uses wood sawdust, rice husk, waste organic, eucalyptus, birch, poplar, fruitwood, bamboo chips, and crop straws as raw materials, through crushing, drying, pelletizing, cooling, packaging, and other processes to produce finished biomass pellets.

The finished pellets are mainly used in biomass power generation, industrial boilers, fireplaces, household barbecues, and other equipment.

Also, RICHI is a professional wood pellet mill manufacturer in China, welcome everyone to follow our wood pellet mill YouTube channel for more video content.

What is wood pellet mill?

MZLH420 Wood pellet mill is a kind of equipment that extrudes powdered biomass or wood raw materials into cylindrical pellets through high-speed, high-temperature, and high-pressure methods.

It is called wood pellet press in the United States and Canada, and the famous brand is CPM pellet mill. There are also very well-known Andritz wood pellet mills and Buhler pellet mills in Europe. In China, in addition to our RICHI Machinery, Zhengchang and Famsun pellet mills are representatives of high quality.

How does a wood pellet mill work?

The powdered biomass or wood raw material enters the pelleting chamber of the pellet mill machine through the conditioner, is mechanically compressed under the action of high temperature and high pressure, and then polymerized and molded through the ring die hole, when they are squeezed out, they become solid cylinders. And finally cut into the required length by the cutter. This manufacturing process is called pelleting.

How does a best wood pellet mill cost?

In general, there are two types of pellet mill, ring die and flat die. Due to the small output, backward technology, and low quality of the flat die pellet machine, what we are discussing here is the price of the ring die mzlh420 wood pellet mill.

If you want to produce wood pellets or other types of biomass pellets, then the first consideration is yield. The output determines the area of the wood pellet factory (the larger the output, the larger the production line), so the larger the output, the greater the investment.

The second influencing factor of the wood pellets machine price is the plan design, and the raw material is directly related to the plan design. Different raw materials need to go through different processing methods, such as peeling, slicing, crushing, drying and so on.

In addition, we will have production lines with different configurations of high, medium and low to choose from. Contact us for a quote if you are ready to invest in a wood pellet plant.

How to build a pellet mill?

Many customers are concerned about how to build a pellet mill or how to start a wood pellet factory? In fact, as long as the following key issues are clarified, investment in pellet production lines will become simple.

- Determine your raw materials. The raw materials determine the development direction of a pellet factory such as the application of pellets, the design and planning of the pellet production line, and so on.

- The output of the production line. Clarify the amount of raw materials you can receive every day, investigate whether there are wood pellet manufacturers of the same type and their output in the surrounding market, and examine the current market size and development prospects. Through a series of commercial investigations, we can basically clarify the size of the pellet production line.

- Determine the land and electricity. Electricity is definitely the standard for industrial electricity use. In addition to meeting the requirements of the production line, the size of the land also needs to reserve staff office areas, raw materials stacking areas, and finished pellet storage areas.

- Choose and purchase mzlh420 wood pellet mill machines and other complete sets of equipment. Note that it is important to choose a real wood pellet mill manufacturer and supplier, with program design capabilities and overseas installation guidance experience.

Application of Wood Pellet Mill in Pellet Plant

Although a single wood pellet mill can also produce wood pellets, in the case of long-term, the customer’s raw materials are various, so we need a complete set of wood pellet production line. To build a wood pellet plant, in addition to a dedicated wood pellet machine, raw material processing equipment, raw material drying equipment, finished pellet cooling equipment, etc. are still required.

Below are our RICHI Machinery’s installed wood pellet plants in some countries for reference only. If you want to invest in a wood pellet production plant, contact us today for a complete pellet production solution and a quotation for all equipment.

Wood Pellet Production Line in Poland

- Project name: wood pellet plant

- Project Country: Poland

- Project Date: January 23, 2019

- Project capacity: 2-3T/H

- Particle size: 4mm

- Installation period: 15 days

- Factory size (L*W*H): 26m*4m*8m

- Main raw material: wood logs

Wood Pellet Plant in Indonesia

- Project name: wood pellet plant

- Project Country: Indonesia

- Project Date: June 15, 2018

- Project capacity: 1-1.5T/H

- Particle size: 6-8mm

- Installation period: 20 days

- Workshop size (L*W*H): 20m*10m*15m

- Main raw materials: logs, sawdust, wood chips

About RICHI Machinery

RICHI Machinery uses its rich experience to continuously design and update the customer’s pelleting production plan. We continue to make breakthroughs in the production of wood pellet mill, complete wood pellet production line, or the exploration of various raw material pelletizing production solutions.

RICHI is always committed to improving the level of the entire pellet machine manufacturing industry and providing a little energy to drive the pellet production industry around the world.

Cooperative Enterprise:

RICHI Service

Start your wood pellet production business with RICHI Machinery. Turn your waste into profits.

From processing raw material to finished pellets, RICHI designs, builds, and installs complete wood pellet production systems.