Wood Pellet Packing Machine

- Brand Name: RICHI Wood Pellet Packing Machine

- Model: DCS-C50/D, DCS-A50/D, DCS-B50/D, DCS-B50/S, DCS-A50/Y

- Application:

Mainly used in pellet production lines. As the last step of the equipment, the finished product is packaged for storage and transportation.

Wood Pellet Packing Machine For Sale

The pellet packing machine is an operation line with a weighing and packaging system as the core equipment. Users can choose the corresponding equipment for matching purpose according to their requirements for the degree of automation.

The pellet packing machine is suitable for quantitative packaging of granular materials such as rubber pellets, plastic pellets, fertilizer pellets, feed pellets, chemical pellets, wood pellets, and biomass pellets.

Fast speed, high precision, and advanced digital motor cutting method.

Packing Machine For Wood Pellets

The wood pellet packing machine is used to package various particulate materials.

The machine has high working efficiency and low energy consumption. It occupies a small area, high site utilization.

The rolling of the particles is relatively large. Pay attention to the stability and transmission loss of the particles when conveying the belt. The belt conveyor occupies a small space. It is only 3,000 mm long and only 400 mm wide, which greatly increases the space. With the flexibility of the belt, the transmission efficiency can be better guaranteed. At the same time, due to its low weight, it requires less energy consumption. Low energy consumption and high efficiency are the biggest characteristics of the pellet packaging machine. The accuracy of the wood pellet packing machine is 0.2, and the pressure is generally 0.4 to 0.6 atmospheric pressure.

This is the basic situation of the wood pellet packing machine, and we can use it to do a lot of practical work. To reduce a lot of work costs, polypropylene and polyethylene are the best packaging materials.

Wood Pellet Packing Machine Technical Parameters

| Model | DCS-C50/D | DCS-A50/D | DCS-B50/D | DCS-B50/S | DCS-A50/Y |

|---|---|---|---|---|---|

| Application | Pellet | Powder | Pellet/Powder | Pellet/Powder | Premix |

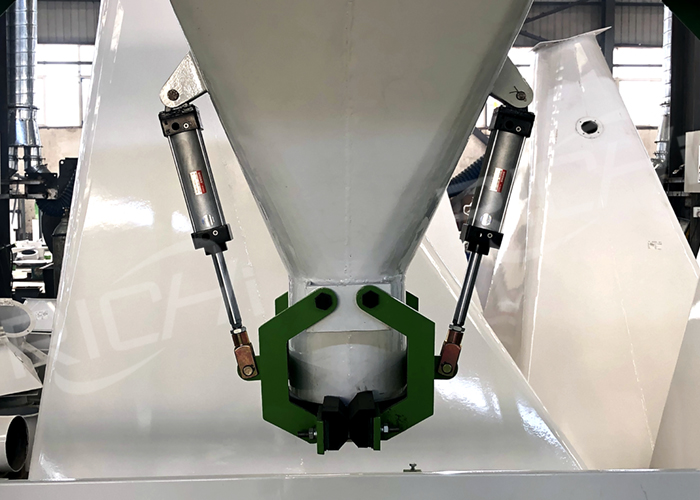

| Feeding Method | Gravity | Screw | Belt | Belt | Screw |

| Speed | 6-8bags/min | 6-8bags/min | 6-8bags/min | 10-12bags/min | 6-8bags/min |

| Power | 1.1kw | 3kw | 3kw | 5kw | 3kw |

| Precision | static±0.1% dynamic±0.2% | static±0.1% dynamic±0.2% | static±0.1% dynamic±0.2% | static±0.1% dynamic±0.2% | static±0.1% dynamic±0.2% |

| Temperature Range | -10~40℃ | -10~40℃ | -10~40℃ | -10~40℃ | -10~40℃ |

| Air Source | 0.4-0.6MPa 1.5m3/h | 0.4-0.6MPa 1.5m3/h | 0.4-0.6MPa 1.5m3/h | 0.4-0.6MPa 1.5m3/h | 0.4-0.6MPa 1.5m3/h |

Packaging System For Pellet Production Line -- RICHI MACHINERY

Some considerations for wood pellet packing machine.

- Before starting each time, check and observe whether there are any abnormalities around the machine;

- When the machine is in operation, it is strictly forbidden to approach or touch the moving parts with your body, hands and head!

- When the machine is running, it is strictly forbidden to extend your hands and tools into the sealing tool holder!

- When the machine is working normally, it is strictly forbidden to switch the operation buttons frequently, and it is strictly forbidden to frequently change the parameter setting value at will;

- Long-term operation at super high speed is strictly prohibited;

- It is forbidden for two or more colleagues to operate the various switch buttons and mechanisms of the machine; the power should be turned off during maintenance and maintenance; when multiple people are debugging and repairing the machine at the same time, they must communicate with each other and indicate to prevent accidents caused by incoordination.

Wood pellet packing machine repair and maintenance.

The maintenance of the wood pellet packing machine is essential for long-term use.

Machine parts lubrication

- The box part of the machine is equipped with an oil meter. You should add all the oil once before starting up. You can add it in the middle according to the temperature rise and operating conditions of each bearing.

- The worm gear box must store oil for a long time. The oil level of the worm gear is such that all the worm gear invades the oil. If it is used frequently, the oil must be replaced every three months. There is an oil plug at the bottom, which can be used to drain the oil.

- When refueling the machine, don’t let the oil spill out of the cup, let alone flow around the machine and on the ground. Because oil easily pollutes materials and affects product quality.

Care instructions

- Check the parts regularly, once a month, check whether the worm wheel, worm, bolts on the lubricating block, bearings and other movable parts are flexible and wearable. Any defects should be repaired in time and should not be used reluctantly.

- The machine should be used in a dry and clean room, and should not be used in places where the atmosphere contains acids and other gases that are corrosive to the body.

- After the machine is used or stopped, the rotating drum should be taken out to clean and brush the remaining powder in the bucket, and then install it, ready for the next use.

- If the wood pellet packing machine is out of service for a long time, the whole body of the machine must be wiped and cleaned, and the smooth surface of the machine parts should be coated with anti-rust oil and covered with a cloth canopy.